The Hidden World of Automotive Microfluidics

Beneath the gleaming exterior and thunderous engine of modern vehicles lies a microscopic realm that's revolutionizing car performance and efficiency. Automotive microfluidics, a cutting-edge field at the intersection of engineering and physics, is quietly transforming how cars operate. From precise fuel delivery to advanced cooling systems, this miniature technology is making waves in the automotive industry, promising enhanced performance, improved fuel economy, and reduced emissions.

The Foundations of Automotive Microfluidics

Microfluidics in automotive applications is rooted in the principles of fluid dynamics at the microscale. At this level, fluid behavior differs significantly from what we observe in larger systems. Surface tension, capillary forces, and laminar flow dominate, allowing for unprecedented control over fluid movement and interaction.

The journey of microfluidics in the automotive sector began in the early 2000s, with initial research focusing on miniaturizing fuel injection systems. Engineers realized that by precisely controlling droplet size and distribution, they could significantly improve combustion efficiency. This revelation sparked a wave of innovation, leading to the development of microfluidic devices for various automotive applications.

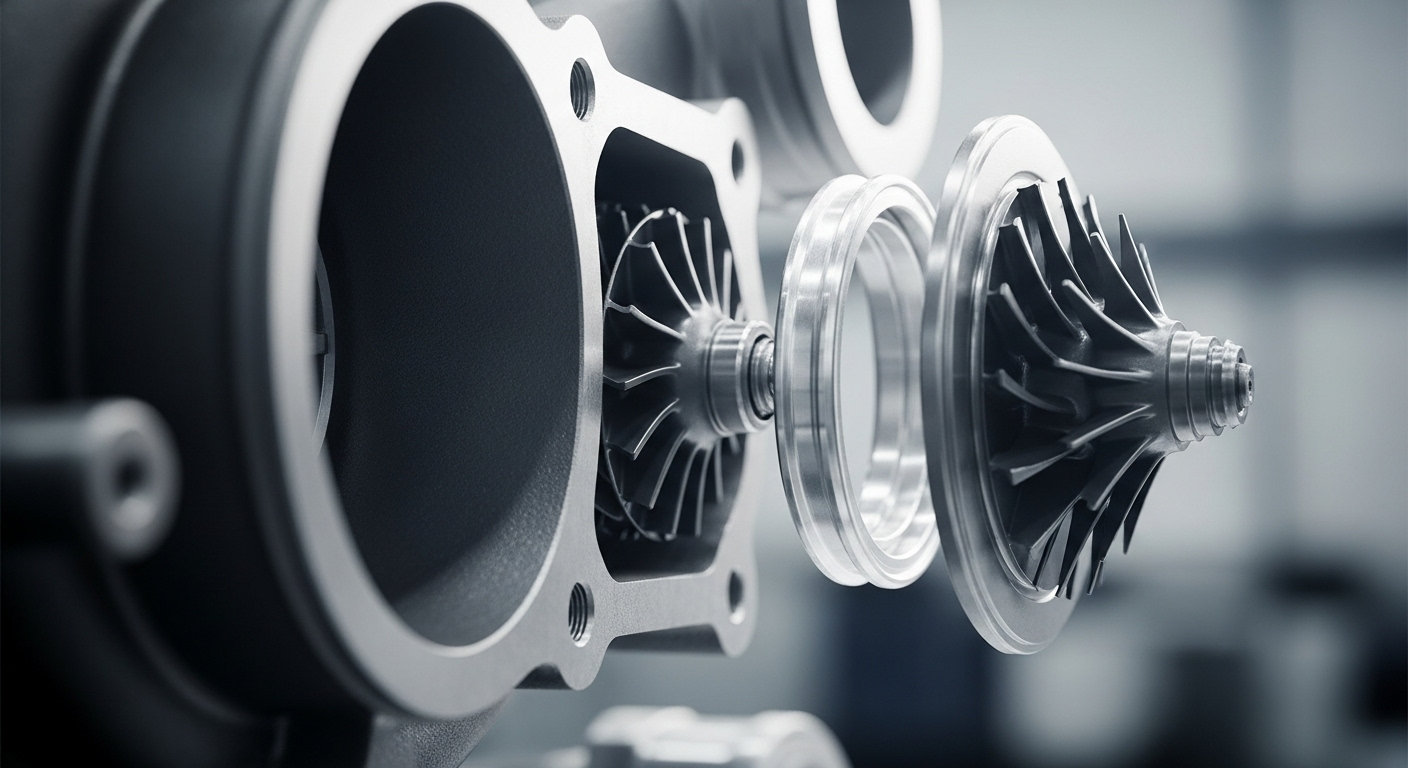

Precision Fuel Delivery: A Microscopic Revolution

One of the most prominent applications of microfluidics in automobiles is in fuel delivery systems. Traditional fuel injectors, while effective, lack the precision needed for optimal fuel economy and emissions control. Microfluidic injectors, on the other hand, can produce droplets as small as a few micrometers in diameter, allowing for near-perfect atomization of fuel.

This level of precision results in more complete combustion, translating to increased power output and reduced fuel consumption. Moreover, the ability to control droplet size and distribution dynamically allows engines to adapt to varying driving conditions in real-time, further enhancing efficiency.

Thermal Management: Keeping Cool at the Microscale

Engine cooling is another area where microfluidics is making significant strides. Traditional cooling systems rely on large volumes of coolant circulating through the engine. While effective, these systems are often bulky and energy-intensive. Microfluidic cooling channels, etched directly into engine components, offer a more elegant solution.

These microscopic channels allow for targeted cooling of specific engine areas, ensuring optimal temperature distribution. The increased surface area-to-volume ratio of these channels results in more efficient heat transfer, potentially reducing the overall cooling system size and weight. This not only improves engine performance but also contributes to better fuel economy through weight reduction.

Lubricant Distribution: Friction’s Microscopic Nemesis

Friction is the enemy of efficiency in any mechanical system, and automobiles are no exception. Microfluidic lubricant distribution systems are emerging as a powerful tool in the fight against friction. By precisely controlling the flow and distribution of lubricants at the microscale, these systems ensure that every critical component receives the optimal amount of lubrication.

This precision goes beyond simply reducing friction. It also allows for the use of specialized lubricants tailored to specific components, further enhancing performance and longevity. The result is not only improved efficiency but also extended engine life and reduced maintenance requirements.

Sensor Integration: The Nervous System of Future Cars

Microfluidics is not limited to fluid control; it’s also paving the way for advanced sensor systems in automobiles. Microfluidic sensors can detect minute changes in fluid properties, from viscosity to chemical composition, providing real-time data on engine health and performance.

These sensors can be integrated directly into critical systems, offering continuous monitoring without the need for invasive testing. For example, microfluidic oil quality sensors can detect contamination or degradation long before it becomes a problem, allowing for proactive maintenance and preventing costly repairs.

Challenges and Future Prospects

While the potential of automotive microfluidics is immense, challenges remain. Manufacturing complex microfluidic systems at scale is technically demanding and can be costly. Ensuring the reliability of these microscopic components in the harsh automotive environment is another hurdle that engineers are working to overcome.

Despite these challenges, the future of automotive microfluidics looks bright. As manufacturing techniques improve and costs decrease, we can expect to see wider adoption of this technology across the automotive industry. The integration of microfluidics with other emerging technologies, such as artificial intelligence and advanced materials, promises to unlock even more possibilities.

In conclusion, automotive microfluidics represents a paradigm shift in how we think about vehicle performance and efficiency. By harnessing the power of fluids at the microscale, engineers are pushing the boundaries of what’s possible in automotive design. As this technology continues to evolve, it’s poised to play a crucial role in shaping the future of transportation, driving us towards a more efficient and sustainable automotive landscape.