Workforce Upskilling for Evolving Industrial Demands

The industrial landscape is undergoing rapid transformation, driven by technological advancements and shifting global demands. To remain competitive and foster growth, businesses worldwide are increasingly recognizing the critical need to invest in workforce upskilling. This proactive approach ensures that employees possess the necessary skills to navigate new operational paradigms, embrace innovation, and contribute effectively to modern industrial processes, from enhanced manufacturing techniques to sophisticated supply chain management.

The industrial sector is experiencing a profound evolution, characterized by the integration of advanced technologies and a constant push for greater efficiency and sustainability. This shift necessitates a corresponding evolution in the capabilities of the workforce. Upskilling, the process of teaching employees new skills, is no longer a peripheral concern but a strategic imperative for enterprises aiming to thrive in this dynamic environment. It empowers employees to adapt to new tools, processes, and methodologies, ensuring that the human element remains central to industrial progress.

Adapting to New Manufacturing and Production Paradigms

Modern manufacturing is increasingly characterized by advanced automation and digitalization. Traditional production lines are giving way to smart factories where machines, sensors, and data analytics work in concert. For the workforce, this means a transition from repetitive manual tasks to roles involving oversight, programming, and maintenance of complex systems. Upskilling programs can focus on areas such as operating advanced machinery, understanding data outputs for quality control, and troubleshooting automated processes. This ensures that employees are not displaced by technology but rather become integral to its effective deployment, enhancing overall production efficiency.

Enhancing Logistics and Supply Chain Management

The intricacies of global supply chain and logistics demand a highly skilled workforce capable of leveraging technology for optimized operations. From predictive analytics for inventory management to real-time tracking systems, the tools available for logistics professionals are becoming more sophisticated. Upskilling in this domain often involves training in enterprise resource planning (ERP) systems, data interpretation, and strategic planning to navigate complex global networks. A well-trained workforce can significantly improve delivery times, reduce operational costs, and build more resilient supply chains, directly impacting business performance and customer satisfaction.

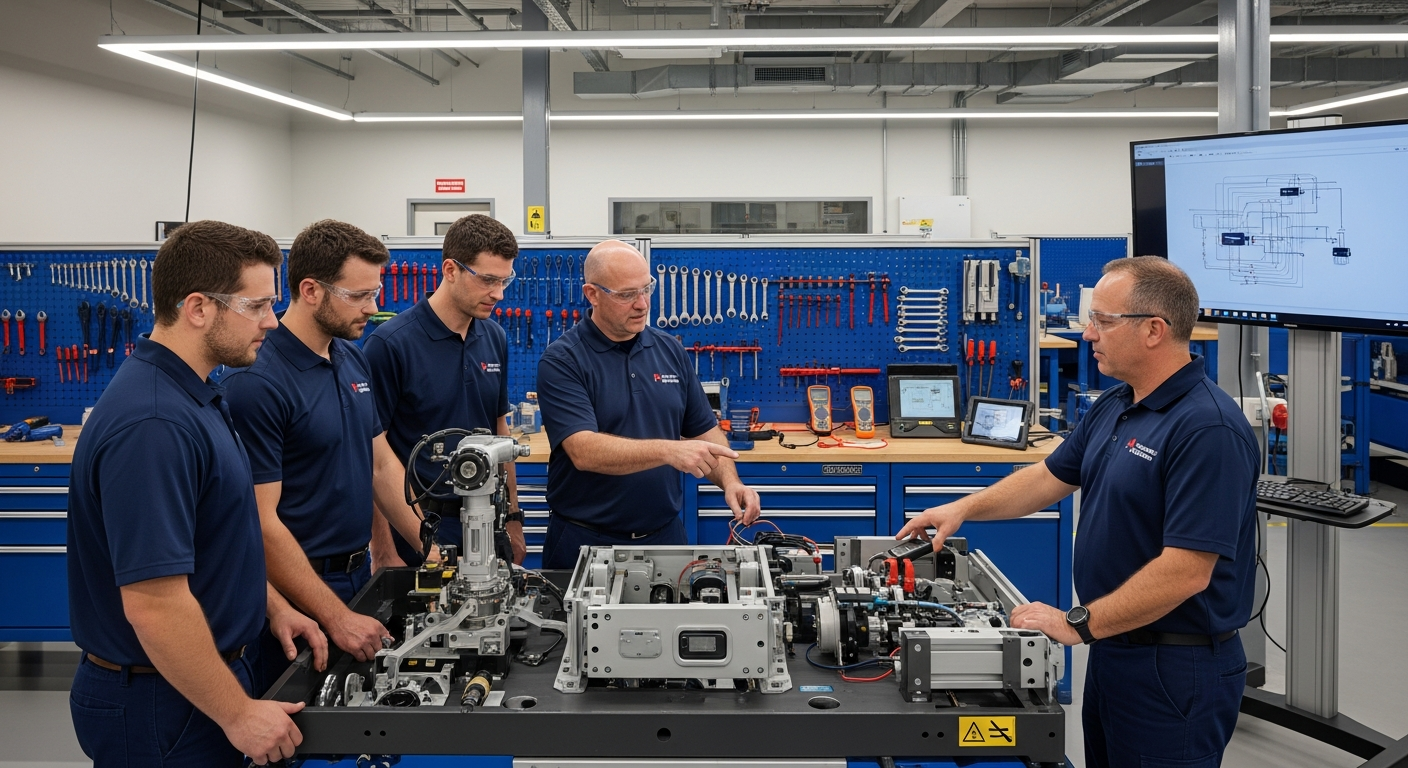

Integrating Automation and Robotics into Operations

Automation and robotics are reshaping the industrial floor, bringing about significant changes in how operations are conducted. While these technologies promise increased efficiency and precision, their successful implementation depends heavily on a workforce that can effectively manage, program, and interact with them. Upskilling initiatives should cover areas like robotic programming, human-robot collaboration, and the maintenance of automated systems. This prepares employees for roles that require a blend of technical expertise and problem-solving skills, ensuring seamless integration of new technologies and maximizing their potential for innovation and productivity.

Fostering a Culture of Innovation and Technology Adoption

Beyond specific technical skills, upskilling also plays a crucial role in cultivating a forward-thinking culture within an organization. Encouraging continuous learning and development helps employees embrace new technology and contribute to strategic innovation. This includes training in digital literacy, understanding emerging technologies, and developing problem-solving skills that can drive new ideas and improvements across the enterprise. A workforce that is continuously learning is better equipped to identify opportunities for improvement, implement new processes, and contribute to the long-term sustainability and growth of the business, making it more agile and responsive to market changes.

Prioritizing Workforce Safety and Sustainability Practices

As industrial processes evolve, so do the considerations for workforce safety and environmental sustainability. Upskilling programs must integrate training on new safety protocols related to advanced machinery, hazardous materials, and digital security within industrial control systems. Additionally, education on sustainable manufacturing practices, waste reduction, and energy efficiency empowers employees to contribute to the company’s environmental goals. This dual focus ensures not only the well-being of the workforce but also the responsible operation of the enterprise, aligning with global standards for ethical and sustainable business practices.

Workforce upskilling is an essential investment for any industrial business aiming to thrive in the modern era. By equipping employees with updated skills in areas such as operations, manufacturing, logistics, automation, and digital technology, companies can enhance efficiency, drive innovation, and ensure long-term sustainability. This strategic approach to human capital development is key to navigating the complexities of evolving industrial demands and maintaining a competitive edge in the global marketplace.